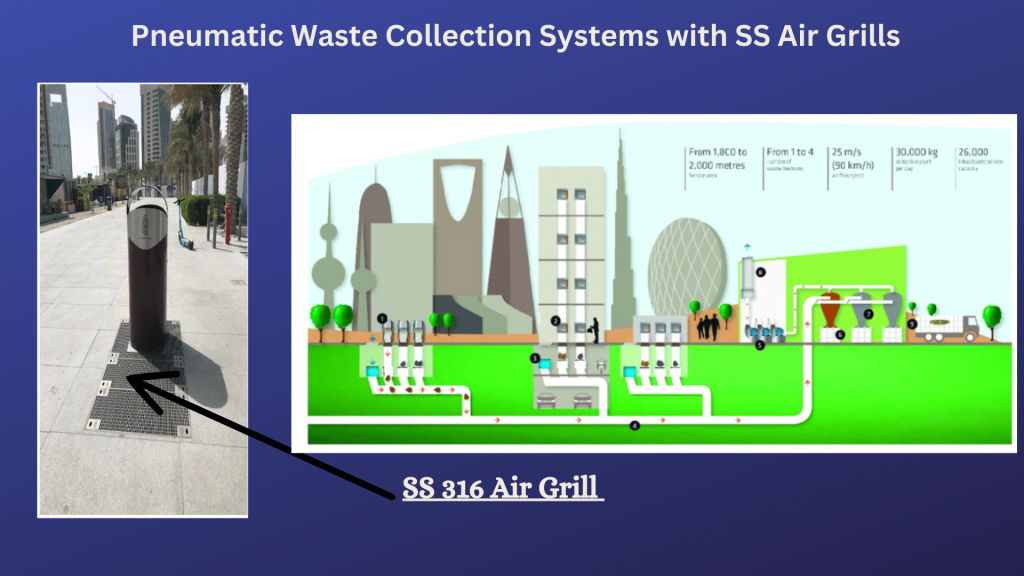

Revolutionizing Waste Management with SS Air Grills: A Game-Changer for Pneumatic Waste Collection Systems

In the bustling metropolis of Lusail city, Qatar, innovation is not just a buzzword; it’s a way of life. Spearheading this drive for ingenuity is our West Coast team, whose groundbreaking design of Stainless Steel (SS) Air Grills is redefining the landscape of waste management, particularly in the realm of Pneumatic Waste Collection Systems (PWCS). The Pencil Heel Grating Advantage Picture this: a pedestrian strolling along the footpath, adorned in sleek pencil heel sandals, amidst the urban hustle and bustle. Now, imagine this same scenario with the added assurance of stability and safety, courtesy of our pencil heel-type grating SS Air Grills. These ingeniously designed grills not only enhance the walking experience for individuals donning pencil heels but also serve a crucial role in waste management. One of the primary benefits of the pencil heel grating design is its ability to prevent large garbage particles from passing through, effectively blocking the grill and ensuring a cleaner environment. Additionally, the structural integrity of the grating provides much-needed support for pedestrians, especially during maintenance activities, ensuring their safety at all times. Unparalleled Design Excellence At the heart of our SS Air Grill design is a commitment to both functionality and aesthetics. With meticulously engineered close spacing of bars, these grills not only deliver superior performance but also elevate the visual appeal of urban landscapes. The result? An esthetic effect that seamlessly blends with the surrounding environment, as showcased in the accompanying photograph. Structural Stability for Unmatched Performance In a city where every element must withstand the rigors of daily life, structural stability is non-negotiable. That’s why our SS Air Grills are built to meet B125 load class capacity standards, ensuring resilience in the face of demanding conditions. Whether it’s supporting pedestrian traffic or enduring the weight of waste collection, these grills stand tall, delivering unmatched performance every step of the way. Empowering Progress, One Grill at a Time As we continue to pioneer advancements in waste management technology, our SS Air Grills stand as a testament to innovation with a purpose. By seamlessly integrating functionality, safety, and esthetics, we’re not just revolutionizing waste collection; we’re shaping the future of urban living. Join us as we pave the way towards cleaner, safer, and more sustainable cities, one grill at a time.

Choosing Between FRP and Aluminium: Understanding Material Properties

In the realm of material selection for structural components, the debate between Fiberglass Reinforced Plastic (FRP) and Aluminium often surfaces. Both possess distinct qualities that cater to diverse needs, be it corrosion resistance, strength, stiffness, impact resistance, or environmental impact. Let’s delve into the core differences between these materials to help you make an informed decision for your projects. Corrosion Resistance: FRP exhibits impressive resistance to a broad spectrum of chemicals and remains unaffected by moisture. However, direct exposure to UV rays necessitates painting. On the other hand, Aluminium boasts excellent corrosion resistance in seawater and saline atmospheres. It can be further fortified through anodizing or coatings, unlike FRP, which is vulnerable to UV exposure due to its composite nature. Strength and Stiffness: While FRP holds good strength along the length of its fibers, its flexural strength remains lower than Aluminium. The direction of fiber alignment dictates FRP’s strength, making its true capacity challenging to determine accurately. Aluminium, being a homogeneous metal, offers higher flexural strength and retains elasticity after loading and unloading, unlike FRP, which tends to remain in a plastic stage upon loading. Impact Resistance: FRP’s inability to absorb impact load stands in contrast to Aluminium’s superior resistance. The latter, although occasionally deforming under extreme impact, typically remains in its elastic stage without entering the plastic stage, making it more resilient. Environmental Impact: Here’s a significant differentiator: FRP, being a petro-based polymer resin, isn’t biodegradable, posing a threat to the environment. Conversely, Aluminium, a naturally occurring metal, is biodegradable, making it a greener choice. Other Factors: In terms of installation, Aluminium triumphs due to ease, while FRP may demand more time due to its span limitations. Additionally, Aluminium boasts negligible maintenance compared to FRP, which requires more attention due to its vulnerability to UV rays. Conclusion: Considering their unique attributes, both FRP and Aluminium have their place in various applications. For short-term projects requiring corrosion resistance and moderate strength, FRP might suffice. In contrast, Aluminium stands as a durable, environmentally friendly option with higher strength and longevity, making it a superior choice for long-term structural requirements. Understanding the intricacies of these materials helps in making informed decisions tailored to specific project needs. So, when selecting between FRP and Aluminium, weigh these factors judiciously to achieve the desired performance and durability for your project.